BLOGS

Innovation in Metal Finishing: The Role of Grinding Wheel Flap Discs

Sep 24,2025

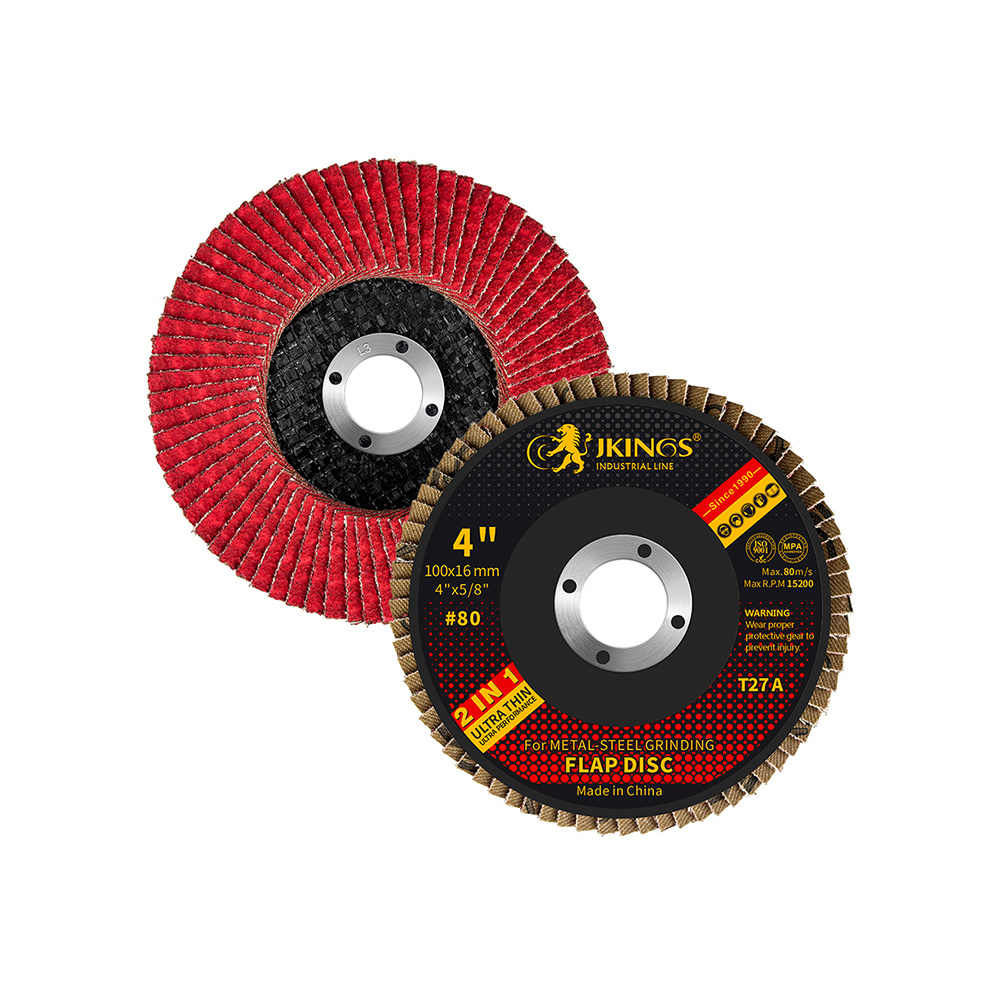

In workshops and industrial settings worldwide, grinding wheel flap discs have become an indispensable tool for professionals seeking efficiency and versatility in material processing. These composite tools combine the aggressive material removal of grinding wheels with the refined finishing capability of flap discs, offering a balanced solution for various metalworking applications.

Grinding wheel flap discs consist of overlapping abrasive flaps mounted on a rigid grinding wheel body. This hybrid design allows operators to perform multiple tasks—such as heavy stock removal, weld blending, deburring, and surface finishing—without switching tools. The structure promotes consistent performance and reduces downtime, making them particularly valuable in high-production environments like metal fabrication, shipbuilding, and automotive manufacturing.

A key functional advantage lies in their ergonomic design. The flap disc segment dissipates heat effectively, reducing the risk of thermal damage to workpieces. This is critical when working with heat-sensitive materials like stainless steel or aluminum. Additionally, the continuous wear of the abrasive flaps ensures a constant contact area, contributing to a more uniform finish over the disc’s lifespan.

These tools are widely used across industries for applications including weld seam smoothing, edge blending, corrosion removal, and surface conditioning. In structural steel construction, flap disc tools help achieve clean, pre-paint surfaces. Meanwhile, in maintenance and repair operations, they facilitate rapid processing of complex components with minimal operator fatigue.

While grinding wheel flap discs deliver significant benefits, their performance depends on appropriate selection. Factors such as abrasive grain type, backing material, and grit size must align with the workpiece material and operation requirements. For instance, zirconia alumina abrasives offer durability for tough alloys, while aluminum oxide may suffice for general-purpose carbon steel.

As manufacturing demands evolve, so does the technology behind abrasive solutions. Innovations in bond systems and abrasive distributions continue to enhance the functionality and safety of these tools. For end-users, understanding the proper use and limitations of grinding wheel flap discs is essential for achieving optimal results in grinding and finishing operations.

RELATED NEWS

Stricter Environmental Regulations Usher in a Green Revolution in the Cutting Disc Industry

By 2028, the penetration rate of environmentally friendly cutting discs is expected to surpass 60%, marking the arrival of a refined, professional, and sustainable new era for the industry.

Abrasive Wheels Enter the Age of Intelligence: Driving a 300% Boost in Automated Cutting Efficiency

From semiconductors to structural steel, from medical implants to solar panels, intelligent grinding wheels are no longer silent contributors—but vital agents of a smarter, faster, and more sustainable future.

Nanodiamond and Composite Bonding Technology Usher in a New Era of Cutting Disc Performance

With nanodiamond abrasives, intelligent sensors, and green binder systems, the future of cutting is sharper, smarter, and more sustainable than ever before.

Grinding Wheel Flap Discs Company

Grinding wheel flap discs are versatile abrasives. They feature multiple overlapping flaps that offer consistent grinding performance. Ideal for various materials like metal, wood, and stone, these discs can efficiently remove rust, burrs, and old paint.

Cutting Disc Industry Report 2025: A New Era of Precision, Efficiency, and Sustainability

JKINGS, as an emerging force, is committed to pioneering smart manufacturing, ultra-thin disc innovation, and sustainable production—aiming to become a global benchmark in next-generation cutting solutions.

Advanced Diamond Blades for Concrete: Enhancing Cutting Efficiency

For professionals working with concrete, the choice of cutting equipment is critical to project success and cost-effectiveness. Diamond blades for concrete represent the pinnacle of cutting technology, engineered specifically to tackle the abrasive and tough nature of concrete materials.