JKINGS PRODUCTS

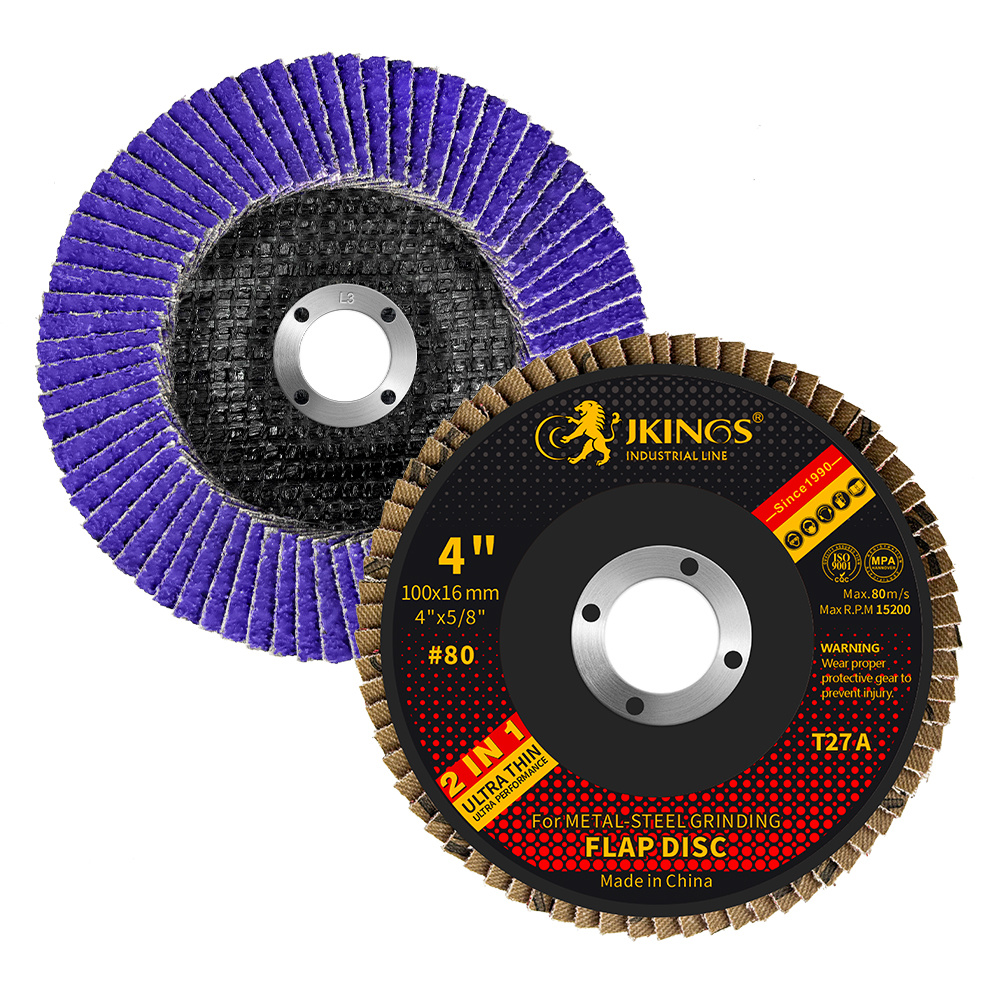

4"x5/8" Flap disc grinding wheel flap discs

Product Description

The JKINGS 100mm (4") Fused Alumina Zirconia Flap Disc is built for aggressive grinding, heavy stock removal, and high-pressure applications.

Using Fused Alumina Zirconia abrasive grains, this disc provides a self-sharpening effect, superior durability, and longer lifespan compared to standard Aluminium Oxide discs.

It ensures smooth contact and efficient material removal, making it ideal for stainless steel, high-tensile alloys, and other tough metals.

The reinforced fiber backing delivers maximum stability, high break resistance, and extended durability, making it perfect for heavy-duty industrial grinding applications.

The grinding wheel flap disc is an advanced and versatile abrasive tool engineered for high-performance metalworking and surface conditioning. It masterfully combines the aggressive stock removal capability of a rigid grinding wheel with the refined, contour-conforming finish of a flexible sanding flap. This unique design features overlapping abrasive flaps, typically made from robust materials like Zirconia Alumina, which are radially arranged and bonded to a reinforced fiberglass backing plate. This construction allows the grinding wheel flap disc to excel in a wide range of tasks, from heavy weld removal and beveling to smooth blending and finishing, all with a single tool.

Engineered for durability and efficiency, the high-performance grinding wheel flap disc offers significant advantages over traditional abrasives. The use of premium Zirconia Alumina grains provides a self-sharpening effect, ensuring consistent cutting action and a longer service life, even under high-pressure applications. The reinforced backing plate delivers maximum stability and break resistance, which is critical for safety and performance in demanding industrial environments. This makes the disc perfectly suited for working on challenging materials such as stainless steel, high-tensile alloys, and other tough metals.

By streamlining the workflow and reducing the need for multiple tools, the grinding wheel flap disc significantly enhances productivity in metal fabrication, welding shops, and construction. Its ability to maintain a consistent surface finish without deep gouging, while still allowing for aggressive material removal, makes it an indispensable asset for professionals seeking both power and precision. The grinding wheel flap disc is the ultimate solution for achieving a superior finish efficiently and reliably, transforming rough surfaces into perfectly prepared ones.

Product Advantages

1. Self-Sharpening Effect

Fused Alumina Zirconia grains continuously fracture, exposing fresh cutting edges.

2. Superior Durability

Longer lifespan compared to standard Aluminium Oxide discs.

3. High Heat & Load Resistance

Prevents overheating and maintains efficiency during extended grinding.

4. Ideal for Heavy-Duty Applications

Designed for tough materials, including stainless steel and high-tensile alloys.

5. Consistent Cutting Power

Maintains high removal rates throughout its lifespan.

Applications

1. Heavy Metal Grinding

Designed for high-pressure grinding of stainless steel and tough alloys.

2. Weld Seam Removal

Smooths and polishes welds efficiently.

3. Surface Leveling & Finishing

Provides a smooth finish on flat and contoured surfaces.

4. Industrial Fabrication & Heavy Machinery

Used in shipbuilding, construction, and manufacturing.

4"x5/8" Flap disc grinding wheel flap discs

|

Dia |

Grades Available |

PCS/BOX |

PCS/CTN |

M/S |

|

100x16 |

40#,60#,80#,100#,120# |

20 |

200 |

80m/s |

|

115x22.23 |

20 |

100 |

80m/s |

|

|

125x22.23 |

20 |

100 |

80m/s |

|

|

150x22.23 |

10 |

100 |

80m/s |

|

|

180x22.23 |

10 |

100 |

80m/s |

Certification