BLOGS

Flap Disc for Steel Seeks Balance Between Efficiency and Finish in Metalworking

Sep 17,2025

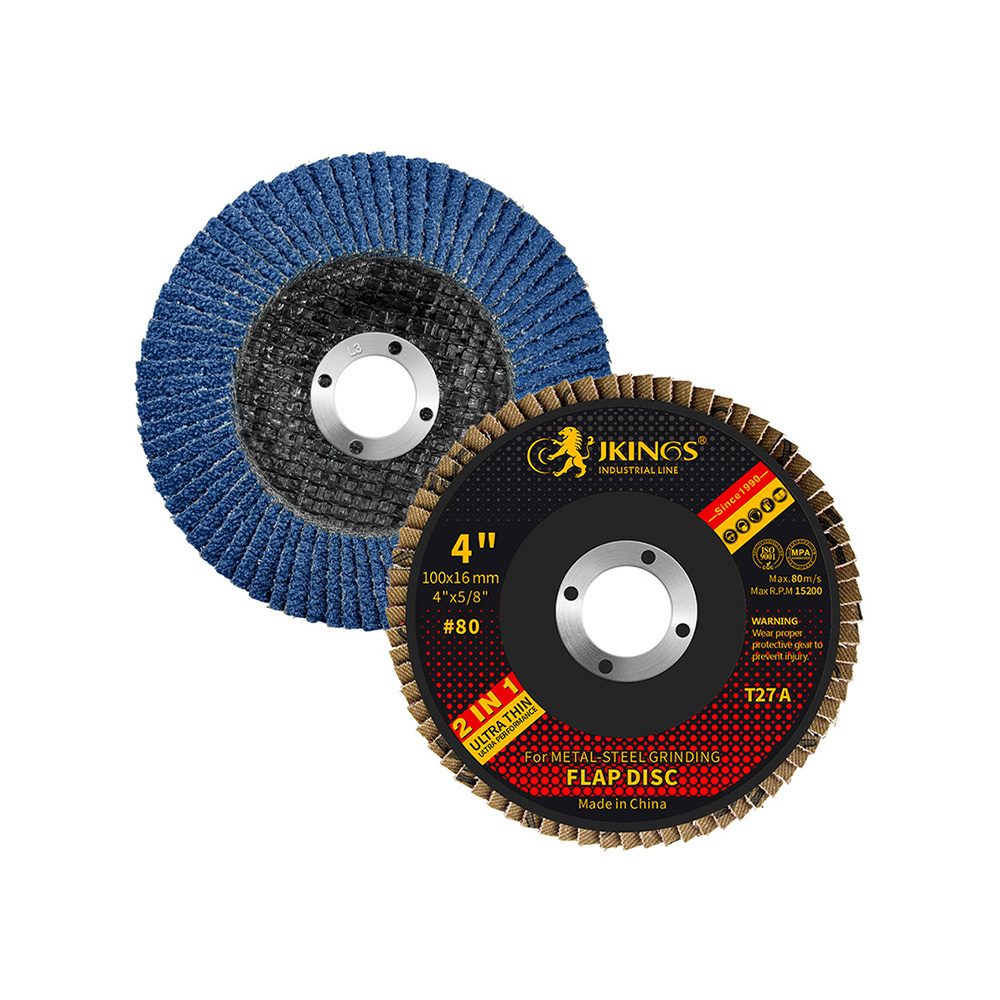

In metal fabrication and welding shops, the pursuit of efficiency is constant, driving the evolution of even the most common consumables. The Flap Disc, a hybrid abrasive tool, has become a standard for operators tackling a primary challenge: transitioning efficiently between heavy stock removal and final surface finishing on Stainless Steel and carbon steel, all with a single tool.

A Flap Disc is constructed by bonding numerous overlapping abrasive flaps, typically made from zirconia alumina or aluminum oxide cloth, to a rigid fiberglass backing plate. This design is fundamental to its function. Unlike a rigid grinding wheel that cuts aggressively at a fixed point, the flexible flaps conform to the workpiece's contour. This allows for a larger contact area that dissipates heat more effectively and provides a more uniform scratch pattern. The key operational value lies in its versatility. It can perform tasks that traditionally required multiple tools—starting with aggressive Grinding to remove weld seams or defects and then transitioning to finer Surface Finishing and blending, all without changing discs.

The primary application for these discs is in the Metal Fabrication industry. Welders use them as a primary tool for cleaning and blending welds, removing rust, and deburring edges on fabricated steel structures. In the automotive repair sector, they are employed for bodywork, smoothing out panels, and preparing surfaces for painting. Their ability to minimize gouging and leave a more consistent finish compared to hard discs makes them particularly valuable for working on expensive materials like Stainless Steel, where preserving material integrity and achieving a specific finish are critical.

The development of the Flap Disc focuses on material science and construction. The choice of Abrasive Grain—such as the highly durable zirconia alumina for long life on hard steels—and the bonding agents that hold the grains are crucial for performance. The density and arrangement of the flaps directly influence the aggressiveness of the cut and the final finish quality. Manufacturers continuously refine these elements to extend product life and enhance cut rates, addressing core operational costs related to consumable usage and labor time.

In summary, the Flap Disc for Steel is an engineered solution that addresses the metalworking industry's need for operational efficiency and finish quality. Its role is defined by its dual-action capability, which streamlines workflow and reduces tool inventory, making it an indispensable consumable in environments where time and results are directly measured against cost.

RELATED NEWS

Stricter Environmental Regulations Usher in a Green Revolution in the Cutting Disc Industry

By 2028, the penetration rate of environmentally friendly cutting discs is expected to surpass 60%, marking the arrival of a refined, professional, and sustainable new era for the industry.

Abrasive Wheels Enter the Age of Intelligence: Driving a 300% Boost in Automated Cutting Efficiency

From semiconductors to structural steel, from medical implants to solar panels, intelligent grinding wheels are no longer silent contributors—but vital agents of a smarter, faster, and more sustainable future.

Nanodiamond and Composite Bonding Technology Usher in a New Era of Cutting Disc Performance

With nanodiamond abrasives, intelligent sensors, and green binder systems, the future of cutting is sharper, smarter, and more sustainable than ever before.

Grinding Wheel Flap Discs Company

Grinding wheel flap discs are versatile abrasives. They feature multiple overlapping flaps that offer consistent grinding performance. Ideal for various materials like metal, wood, and stone, these discs can efficiently remove rust, burrs, and old paint.

Cutting Disc Industry Report 2025: A New Era of Precision, Efficiency, and Sustainability

JKINGS, as an emerging force, is committed to pioneering smart manufacturing, ultra-thin disc innovation, and sustainable production—aiming to become a global benchmark in next-generation cutting solutions.

Advanced Diamond Blades for Concrete: Enhancing Cutting Efficiency

For professionals working with concrete, the choice of cutting equipment is critical to project success and cost-effectiveness. Diamond blades for concrete represent the pinnacle of cutting technology, engineered specifically to tackle the abrasive and tough nature of concrete materials.