BLOGS

Innovation in Metal Finishing: The Role of Grinding Wheel Flap Discs

Sep 24,2025

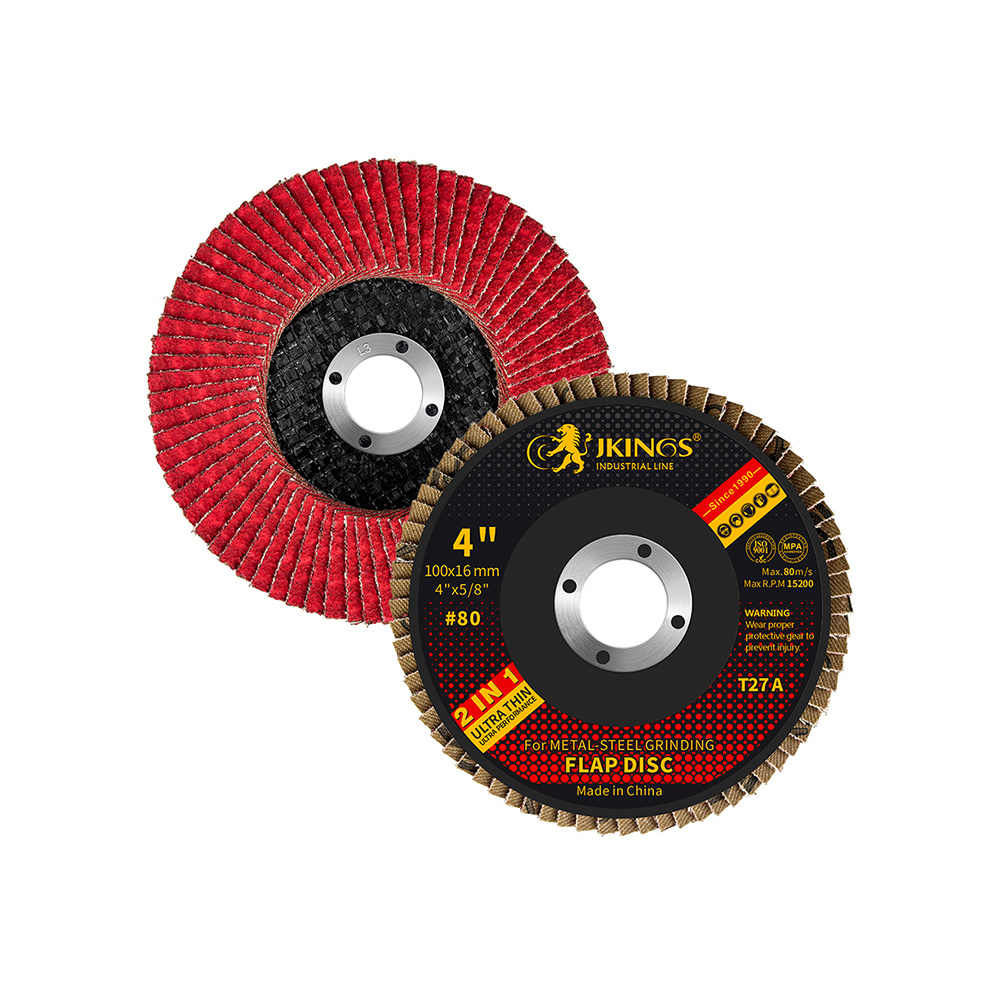

In workshops and industrial settings worldwide, grinding wheel flap discs have become an indispensable tool for professionals seeking efficiency and versatility in material processing. These composite tools combine the aggressive material removal of grinding wheels with the refined finishing capability of flap discs, offering a balanced solution for various metalworking applications.

Grinding wheel flap discs consist of overlapping abrasive flaps mounted on a rigid grinding wheel body. This hybrid design allows operators to perform multiple tasks—such as heavy stock removal, weld blending, deburring, and surface finishing—without switching tools. The structure promotes consistent performance and reduces downtime, making them particularly valuable in high-production environments like metal fabrication, shipbuilding, and automotive manufacturing.

A key functional advantage lies in their ergonomic design. The flap disc segment dissipates heat effectively, reducing the risk of thermal damage to workpieces. This is critical when working with heat-sensitive materials like stainless steel or aluminum. Additionally, the continuous wear of the abrasive flaps ensures a constant contact area, contributing to a more uniform finish over the disc’s lifespan.

These tools are widely used across industries for applications including weld seam smoothing, edge blending, corrosion removal, and surface conditioning. In structural steel construction, flap disc tools help achieve clean, pre-paint surfaces. Meanwhile, in maintenance and repair operations, they facilitate rapid processing of complex components with minimal operator fatigue.

While grinding wheel flap discs deliver significant benefits, their performance depends on appropriate selection. Factors such as abrasive grain type, backing material, and grit size must align with the workpiece material and operation requirements. For instance, zirconia alumina abrasives offer durability for tough alloys, while aluminum oxide may suffice for general-purpose carbon steel.

As manufacturing demands evolve, so does the technology behind abrasive solutions. Innovations in bond systems and abrasive distributions continue to enhance the functionality and safety of these tools. For end-users, understanding the proper use and limitations of grinding wheel flap discs is essential for achieving optimal results in grinding and finishing operations.

RELATED NEWS

The Global Cutting Disc Market Accelerates: Demand for High-Precision Cutting and Technological Upgrades Drive Growth Toward $2.35 Billion by 2031

The Global Cutting Disc Market Accelerates: Demand for High-Precision Cutting and Technological Upgrades Drive Growth Toward $2.35 Billion by 2031

The Global Cutting Disc Industry Restructures: China Shifts from "OEM Factory" to "Technology Export Hub" as Southeast Asia Becomes a Key Market

The Global Cutting Disc Industry Restructures: China Shifts from "OEM Factory" to "Technology Export Hub" as Southeast Asia Becomes a Key Market

JKINGS Showcases High-Performance Abrasive Solutions at the China–Central Asia (Uzbekistan) Trade Fair

JKINGS Showcases High-Performance Abrasive Solutions at the China–Central Asia (Uzbekistan) Trade Fair

Innovation in Metal Finishing: The Role of Grinding Wheel Flap Discs

In workshops and industrial settings worldwide, grinding wheel flap discs have become an indispensable tool for professionals seeking efficiency and versatility in material processing. These composite tools combine the aggressive material removal of grinding wheels with the refined finishing capability of flap discs, offering a balanced solution for various metalworking applications.

Flap Disc for Steel Seeks Balance Between Efficiency and Finish in Metalworking

In metal fabrication and welding shops, the pursuit of efficiency is constant, driving the evolution of even the most common consumables. The Flap Disc, a hybrid abrasive tool, has become a standard for operators tackling a primary challenge: transitioning efficiently between heavy stock removal and final surface finishing on Stainless Steel and carbon steel, all with a single tool.

JKINGS Ultra-Thin Bonded Cutting Discs: Precision Breakthrough Made in China

JKINGS Ultra-Thin Bonded Cutting Discs: Precision Breakthrough Made in China