BLOGS

Diamond Flap Discs Gain Traction in Precision Grinding and Finishing Applications

Oct 31,2025

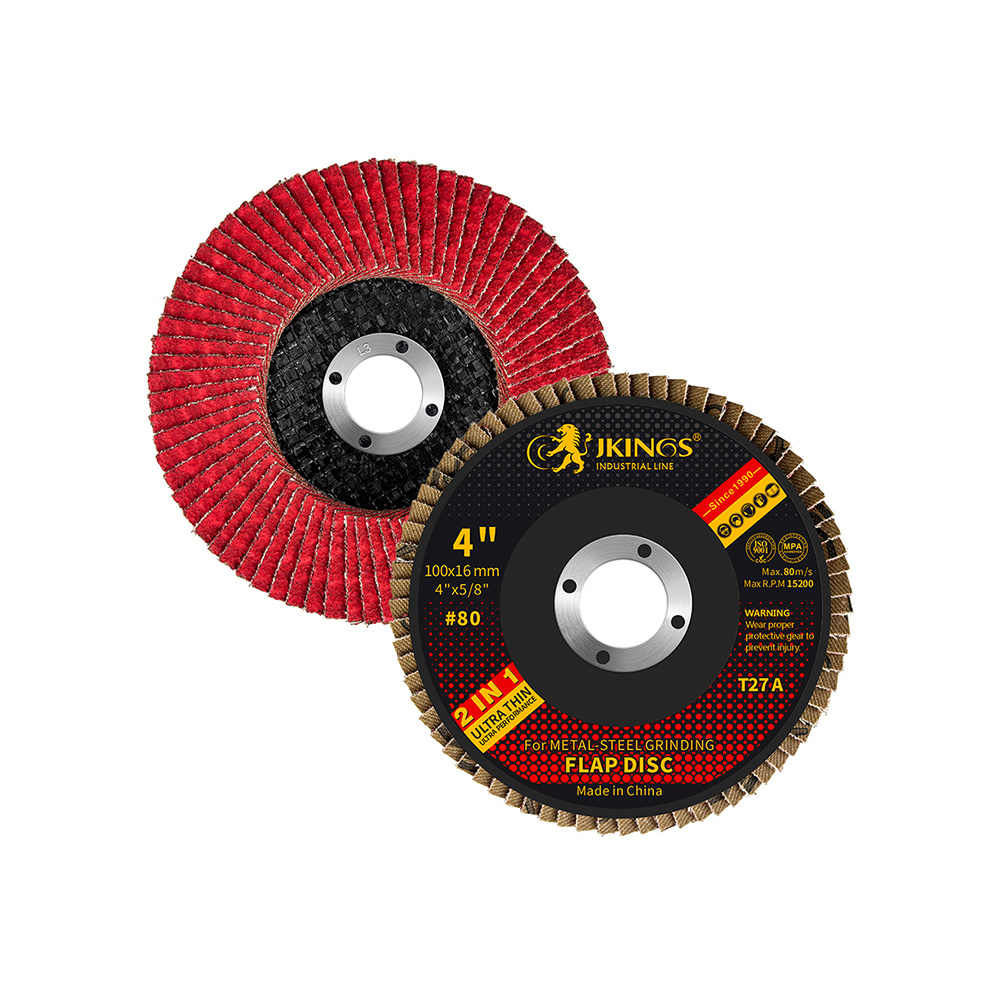

In workshops and industrial settings demanding exceptional durability and a consistent finish, the diamond flap discs are increasingly becoming the abrasive tool of choice for challenging materials. Unlike conventional abrasives that wear down quickly, these tools leverage a robust construction where diamond grains are permanently bonded to overlapping flaps, offering a significant leap in performance and cost-efficiency over time.

The primary function of diamond flap discs is to provide aggressive stock removal and a superior finish on hard, non-ferrous materials where other abrasives fail. They excel in applications involving carbide, ceramics, glass, and certain hardened steels. The unique flexible flap design allows for contour following, reducing the risk of gouging the workpiece and enabling a seamless transition from heavy grinding to fine finishing without changing tools. This versatility is critical in industries such as tool and die manufacturing, foundry work, and weld preparation and blending, where precision and surface integrity are paramount.

A key advantage of advanced diamond flap discs is their engineered design for enhanced performance. Many high-quality versions feature a ventilation system within the backing plate. These airflow holes are not merely for weight reduction; they actively channel air to the working surface, effectively cooling both the tool and the material. This mitigates heat buildup, which can otherwise compromise the material's temper or lead to premature wear of the diamond flap discs themselves. Furthermore, the reinforced fiberglass backing provides crucial safety and stability during high-RPM operations.

The market growth for diamond flap discs reflects a broader industry shift towards specialized, long-life consumables that reduce downtime and improve overall operational efficiency. As manufacturers continue to push the boundaries with harder composites and alloys, the demand for these high-performance abrasives is poised to rise steadily, solidifying their role as an indispensable asset in modern material processing.

RELATED NEWS

Stricter Environmental Regulations Usher in a Green Revolution in the Cutting Disc Industry

By 2028, the penetration rate of environmentally friendly cutting discs is expected to surpass 60%, marking the arrival of a refined, professional, and sustainable new era for the industry.

Abrasive Wheels Enter the Age of Intelligence: Driving a 300% Boost in Automated Cutting Efficiency

From semiconductors to structural steel, from medical implants to solar panels, intelligent grinding wheels are no longer silent contributors—but vital agents of a smarter, faster, and more sustainable future.

Nanodiamond and Composite Bonding Technology Usher in a New Era of Cutting Disc Performance

With nanodiamond abrasives, intelligent sensors, and green binder systems, the future of cutting is sharper, smarter, and more sustainable than ever before.

Grinding Wheel Flap Discs Company

Grinding wheel flap discs are versatile abrasives. They feature multiple overlapping flaps that offer consistent grinding performance. Ideal for various materials like metal, wood, and stone, these discs can efficiently remove rust, burrs, and old paint.

Cutting Disc Industry Report 2025: A New Era of Precision, Efficiency, and Sustainability

JKINGS, as an emerging force, is committed to pioneering smart manufacturing, ultra-thin disc innovation, and sustainable production—aiming to become a global benchmark in next-generation cutting solutions.

Advanced Diamond Blades for Concrete: Enhancing Cutting Efficiency

For professionals working with concrete, the choice of cutting equipment is critical to project success and cost-effectiveness. Diamond blades for concrete represent the pinnacle of cutting technology, engineered specifically to tackle the abrasive and tough nature of concrete materials.